ROOFING IS OUR HERITAGE • QUALITY IS OUR TRADITION

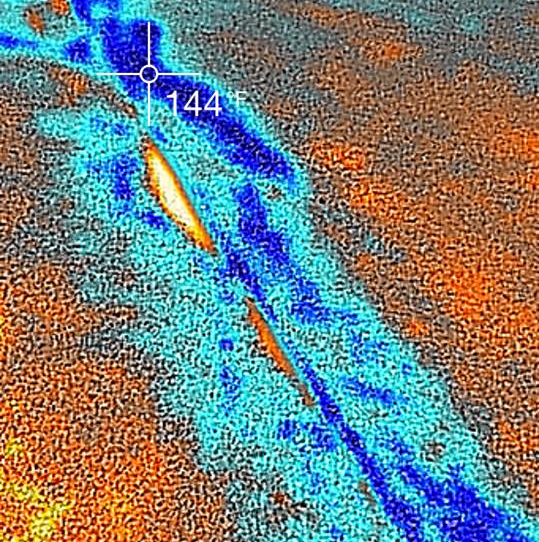

FLIR Imaging

FLIR Imaging

It is estimated that up to 40% of commercial roofs will develop problems within the first year of service. The average life span of these roofs is 7-10 years, but they could last as long 20 years, if they correctly installed and properly maintained.

An infrared inspection should become a part of your annual maintenance program. Infrared imaging stands above all other methods in prolonging the life of a commercial roof.

Infrared inspections are a non-contact and non-destructive testing method to determine active roof leaks. The infrared camera allows a professional thermographer to scan large areas.

Take the first step to making sure your roof is damage-free and prevent costly future repairs. Call Absolute Roofing Services at 770-743-7946.

We also utilize the Tramex Dec Scanner which can detect as little as 3% moisture content in most roof systems and detects moisture up to 3 inches below the roof surface. The combination of these two technologies provides accurate non-destructive results. Traditional roof inspection methods require a grid-type contact sampling (capacitance testing), take a long time to complete, and involve drilling actual holes (core sampling) in the roof membrane. For obvious reasons, this inspection method is definitely not recommended!

Infrared roof inspections work on the principle that different materials in the roof have different thermal masses. In the daytime, the sun heats the roof structure. After the sun sets, the roof begins to cool. If there is a leak in the roofing membrane, the insulation inside the roof will become wet. The wet insulation has a higher thermal mass than the rest of the dry roof structure. Because of the difference, the “wet” areas will maintain heat energy longer than other areas, providing the infrared inspector with a clear picture of the damaged area.

FLIR Imaging

This can save thousands of dollars in repairs and help determine whether a repair would make more sense than a replacement. The temperature difference between damaged and “dry” roofs is very small (typically two to four degrees).

Because of this, it is vital that you have an experienced professional thermographer and a high-resolution infrared camera to perform your inspections.

You will receive a detailed report including CAD drawings along with infrared/digital images of the exact locations of the problem areas.

Have questions about the roof on your commercial property? Call us to today and see why we are the best commercial roofing contractor in Atlanta, GA.